Key takeaways:

- SOLIDWORKS 2018 is planned for release at the end of October 2017.

- CAMWorks has been packaged and released under the SOLIDWORKS banner as SOLIDWORKS CAM.

- The release introduces topology optimization technology from SIMULIA.

On September 26, 2017, Dassault Systèmes hosted industry analysts, technical press, and customers at their Waltham, Massachusetts headquarters for the launch of SOLIDWORKS 2018. The event was also live-streamed over the Internet. Mr. Gian Paolo Bassi, CEO of the SOLIDWORKS brand, welcomed the attendees and noted that “SOLIDWORKS is everywhere,” with 5.1 million users at 261,000 companies around the world. He spoke of the company’s “values, vision, and actions.” He addressed company values that centered on being responsive to customer demands in an ever changing world, and on being responsible, fostering the belief that “technology is a transformative force” in the world. CIMdata recognizes that SOLIDWORKS has gained broad-based acceptance in design and is exceptionally positioned to influence product development.

Mr. Bassi noted that SOLIDWORKS’ vision showed the future of design built on the integration of multiple disciplines and automation through machine learning and artificial intelligence (AI). He spoke of fostering aspects of “assistive, augmented, and autonomous” design. With regard to actions, Mr. Bassi listed SOLIDWORKS support on the desktop as well as on Dassault Systèmes’ 3DEXPERIENCE platform providing users a choice in how they manage their solution.

Smart Manufacturing

The SOLIDWORKS team highlighted four topics in the new release that focused on how “Great Designs get Built.” The first was smart manufacturing and the role model-centric design plays in providing a single source of intelligent information. The team listed a number of improvements to the SOLIDWORKS core that support a complete design-through-manufacturing strategy.

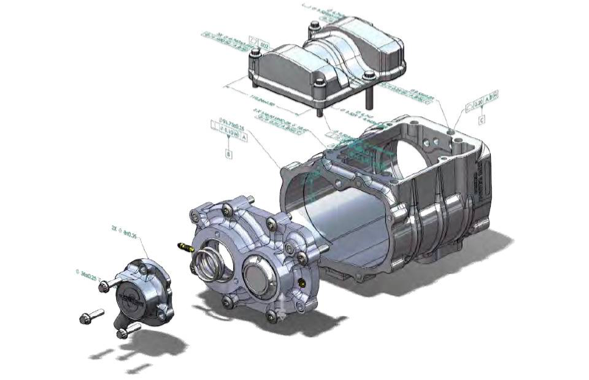

Figure 1–Part Assembly with MBD Annotation (PMI)

(Courtesy of SOLIDWORKS)

The release includes model-based definition (MBD) enhancements and the ability to import foreign data formats (PTC’s CREO, Siemens PLM Software’s NX, Dassault Systèmes’ V5, and ISO STEP 242) with part manufacturing information (PMI). The team touted the ability to generate more accurate 3D PDFs and export ISO STEP AP242 formatted data with machine-readable annotations. CIMdata commends SOLIDWORKS for their continued pursuit of a complete 3D solution from design to manufacturing. Their users will see improved workflows and cost savings.

SOLIDWORKS CAM

As part of the Smart Manufacturing topic and arguably the most impactful aspect of the release was the announcement of SOLIDWORKS CAM. The solution is powered by CAMWorks,[1] a tolerance-based machining solution. SOLIDWORKS CAM offers rules-based part and assembly machining including 2.5-axis milling and 2-axis turning. The solution is fully integrated within SOLIDWORKS so users need not leave the familiar SOLIDWORKS environment. It supports feature recognition and can generate machining operations directly from native SOLIDWORKS or imported foreign data leveraging PMI information. Toolpaths are associative to the model and are automatically updated based on changes to the model. CIMdata welcomes the SOLIDWORKS decision to package and offer their users SOLIDWORKS CAM. It protects the investment of CAMWorks users and adds proven CAM capabilities to SOLIDWORKS.

Next Generation Design

The second topic the SOLIDWORKS team focused on was the release’s enhancements to the design process itself. For the CAD manager, the release contains an Administration Portal which allows assets (software, licenses, etc.) to be managed online. SOLIDWORKS products can be associated to specific users including license information such as serial number and date of expiration. In addition, SOLIDWORKS Online Licensing supports quick changes to move licenses between machines including users’ UI customizations.

Additional work was done for touch-enabled devices including the addition of a touch mode toolbar. The SOLIDWORKS team also added larger context and gesture menus for ease of use. A freehand touch sketching capability is enabled for users of Windows 10 that can automatically convert pen strokes to sketch shapes. CIMdata believes that SOLIDWORKS 2018 users will find these functions will contribute to their ease of use in environments that take them away from their normal office workstations.

Topology Optimization

The premier enhancement under the umbrella of next-generation design is the addition of topology optimization. This emerging technology is gaining interest across numerous product development industries for the generation of optimum product design forms based on engineering load and other constraints. The output of the optimization feeds directly into Additive Manufacturing (AM)/3D printing processes. The technology comes from Dassault Systèmes’ SIMULIA product line and is embedded within SOLIDWORKS 2018. CIMdata spoke with Mr. Bassi after the launch event and discussed how SOLIDWORKS 2018 enables design for AM (DfAM) processes. Mr. Bassi clearly has a passion for changing the way engineers design things for AM. His holistic vision encompasses Generative Design and Topology Optimization to reduce weight and improve the performance of products. He also recognizes education is needed to help engineers transition from traditional design to DfAM, and believes huge gains can be made by engineers once they embrace DfAM into their design processes. For example, a 10-part assembly could become a single AM part thus eliminating significant time and cost throughout the product’s lifecycle, which is a concept he envisions.

Underlying the optimization solution is a reliance on mesh modeling, a new addition to the geometric kernel used by SOLIDWORKS 2018. Mesh modeling introduces the geometric object of a planar triangle as a new construct. Users can modify mesh bodies or generate precise geometric surfaces from meshes. The foundational technology opens up improvements to reverse engineering processes and upgrades the ability to import and manipulate scanned data.

Essential Design Tools

The third topic on the agenda covered a series of enhancements across the SOLIDWORKS 2018 product to improve the design. One such improvement to enhance the user experience is an Assembly Open Progress Indicator. The gauge shows users the timing of opening large product assemblies.

Another user experience improvement that was announced, to the applause of users in the audience, was the ability to mirror 3D sketch geometry. Further additions included the ability to reverse tangent directions on arcs and splines. CIMdata applauds the SOLIDWORKS team’s continued ability to improve the product to meet the detailed requests of its users.

Delivering Great Design

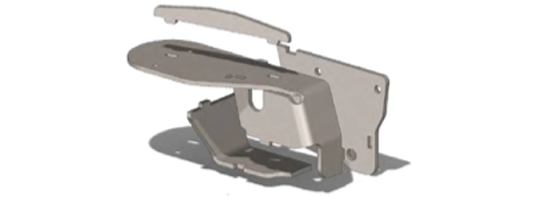

The fourth and final emphasized topic on the agenda addressed enhancements that offered users interesting new ways to design and assemble component models. First, was a Tab and Slot Feature defining an assembly mating of the tab into slot. The ingenious tab and slot feature offer the ability to minimize assembly and set-up costs. It is not restricted to sheet metal parts.

Figure 2–Assembly with Tab and Slot Features

(Courtesy of SOLIDWORKS)

Additional enhancements are included for drawings and eDrawings, such as full STEP AP242 support within eDrawings. SOLIDWORKS Visualize delivers a refreshed user interface, area lights, and virtual reality capabilities.

SOLIDWORKS Manage built atop SOLIDWORKS PDM now offers user project and process management as well as interactive dashboards and reporting.

Summary and Opinion

The forthcoming SOLIDWORKS 2018 release carries on its long tradition of a mix of new capabilities and user-requested enhancements. CIMdata agrees that SOLIDWORKS is one of the very few CAD solutions that is broadly accepted by the product design community and uniquely positioned to help drive new technologies and new design methodologies. CIMdata welcomes the extensive enhancements found in SOLIDWORKS 2018 and believes they will contribute to user success and innovation.